Monitoring of network infrastructure

Monitoring of network infrastructure

case study

The control and monitoring of technological processes is more and more based on network technologies using IP protocol. It is possible to use this protocol not only in Ethernet networks but also in wireless networks (WiFi - Wireless Fiedlity) and while communicating with devices with serial interface (using PPTP - Point to Point Tunneling Protocol), via phone lines, GSM and GPRS. Most devices using this protocol have implemented complete "IP protocol stack" including the application protocol SNMP (Simple Network Management Protocol). This protocol is used already for a long time for the purpose of control and monitoring of network devices within corporate IT systems and gradually, with fast growing industrial Ethernet, it starts to assert also within network infrastructure of technological process control. There are more and more devices of various producers that use SNMP protocol even for transfer of process data such as temperature, pressure, ...

The overview of communication infrastructure connecting individual technological units together as well as superior corporate information system can be obtained based on the information provided by our SAEAUT SNMP OPC Server.

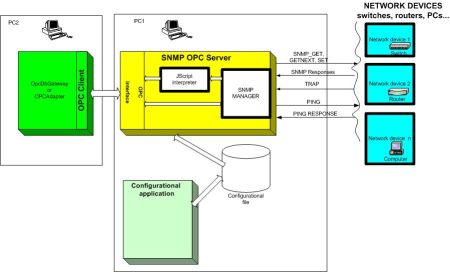

Image 1: Application platform with SAEAUT SNMP OPC Server

With its usage it is possible to determine what communication problems are caused by malfunctions in software applications of particular technological units. Suppliers of technological software applications will not be able to make excuses that their application is working properly and does not cause flooding of communication channels, if the administrator is able to prove from current and historical trends that it is not truth. From acquired data it will be possible to determine when it is necessary to strenghten or modernize the communication infrastructure. A very useful can be to integrate the control and monitoring of network infrastructure into an existing system of supervisory process control - (SCADA - Supervisory Control And Data Acquisition). SNMP OPC Server represents the connection of two technologies - SNMP and OPC. OPC (nowadays interpreted as Open Process Control) is not only a communication, but also a functional standard that ensures the interoperability between devices and software of various producers. SNMP OPC server allows variables, acquired or configured via SNMP protocol, to be converted into a format demanded by software application that includes an OPC client. There are lot of such applications. It is contained not only in every known SCADA application, but also in some dynamic process simulation applications. As a part of the shipment of our server, you can find examples of OPC clients with their source code in C++, MS VB and MS VB.NET. The idea of connection of SNMP and OPC technologies is not new. Our SAEAUT SNMP OPC server has several advantages over solutions of other vendors. First of all, it implements not only the newest OPC standards such as OPC DA 3.0 and OPC AE 1.1, but also OPC XML DA that allows to communicate with it through web services and this way to use it within service oriented architectures (SOA). You can try this with using of XML DA client shipped by us together with its souce code or with the help of a web browser (such as MS Internet Explorer).

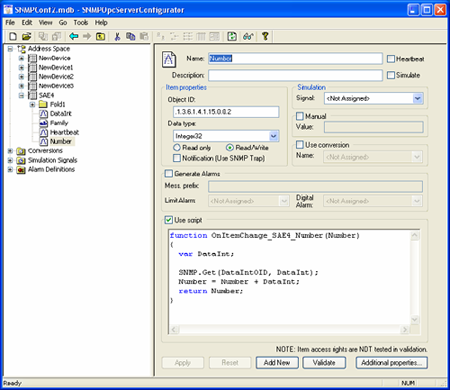

Image 2: SAEAUT SNMP OPC Server configurator with in-built JScript editor

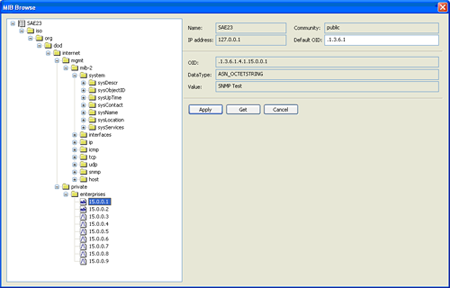

Image 3: MIB Browser of SAEAUT SNMP OPC Servera

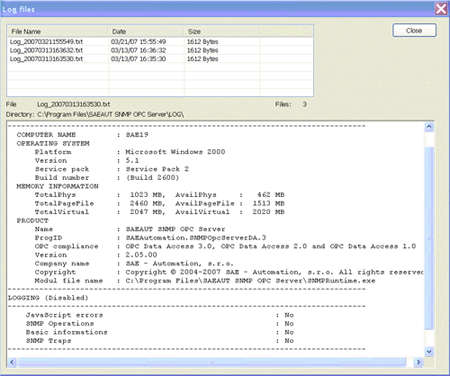

SAEAUT SNMP OPC Server allows to monitor also devices without an active SNMP agent and in a OPC variable to transfer the time delay to a ICMP ping from the server to such device. A very useful can be the function to log and display the activities of OPC server into log files.

Image 4: Selecting "logged" events

Image 5: Browsing log files

Image 6: IP scanner

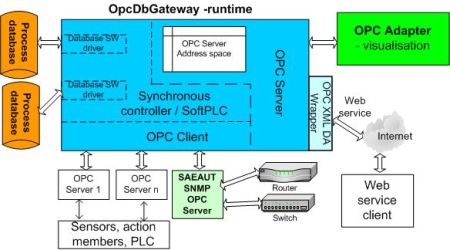

By using our trio of products SAEAUT SNMP OPC server, OpcDbGateway and OPC Adapter you can create a very complex system of control, monitoring, data storage in process databases, alarms, reports, visualisation, logging and data transfer between intranet domains and over Internet.

Image 7: Complex solution of monitoring with our products.